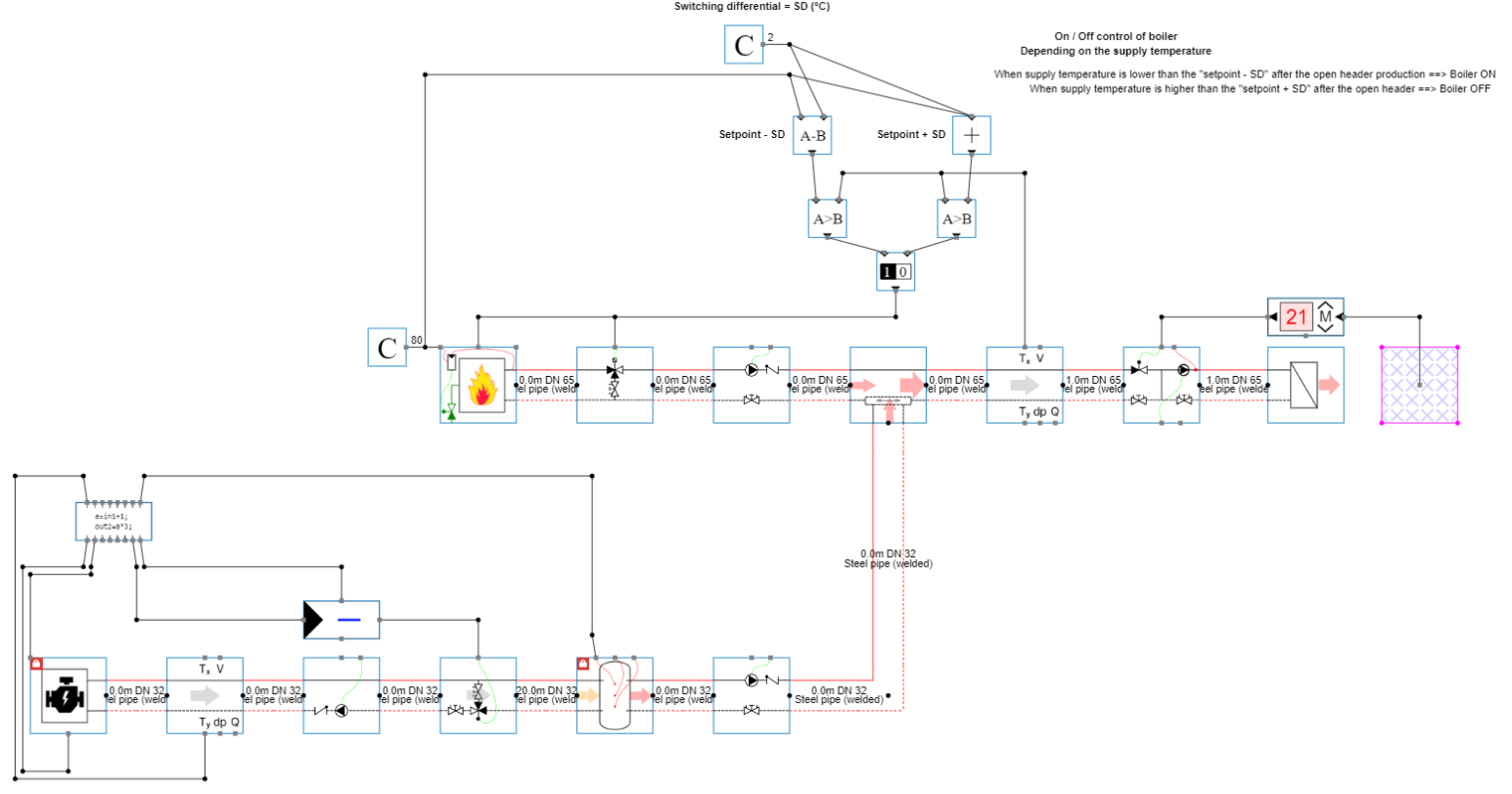

A very common hybrid configuration of CHP systems with boilers is by using an open header (shunt connection). An open header creates an additional hydraulic separation between the two energy-supplying systems. These types of configurations become interesting if there is a need for the possibility of operating these systems together and if it is not wanted to use an additional switching 3-way valve. CHP & boiler - Serial configuration . Make sure that the “Reverse drag flow power on return” block is correctly filled in in order to avoid making design mistakes. Shunt

Working principle

The CHP has a reverse shunt configuration in the return pipe with the boiler. More information about the different configuration possibilities can be found in Hybrid production Heating. The CHP will act as an pre-heater to the boiler. This will result in a slightly lower efficiency of the boilers but using a combination of CHP and boiler systems offer the added value of reducing the overall primary energy consumption through produced electricity.

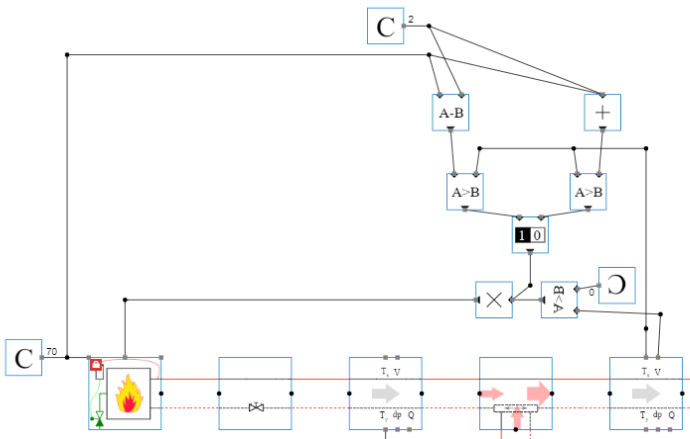

The CHP will pre-heat the return water to a certain temperature. Afterwards, the boiler will increase the temperature further to the desired installation supply temperature. In the case of using an on/off control principle, the boiler is activated when the flow temperature of the system drops under 68°C, and deactivated when the flow temperature rises over 72°C. The activation also includes a check for the minimal flow rate, if the flow rate through the system is insufficient, the boiler won’t be activated. For instance, if the installation is shut down, the temperatures in the pipes will drop but the boiler won’t be activated because there is no flow through the system.

The working principle of the CHP control is explained in CHP - Basic Control

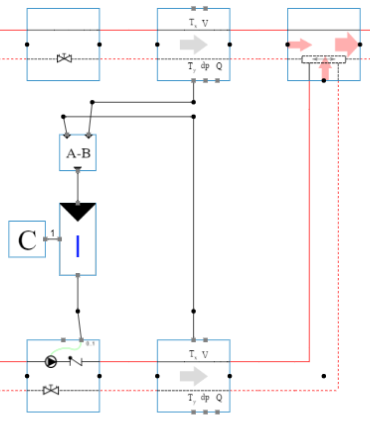

The reverse shunt connection can also have a pump flow control, which measures and controls to a constant temperature difference between the ingoing temperature to the boiler and the supply temperature from the CHP. This is further explained in the template “Pump control - Temperature control over open header - 2 points” found in Advanced pump control.

Parameters that must be changed in order to use this model correctly:

All of the parameters for the boilers and CHP have been explained previously on the CHP & Boiler - Parallel configuration page. The only additional remark is the pump control over the shunt connection. The constant standard temperature difference is set on 1 degree, but can even be reduced up to 0.5 degrees.

Keep in mind that the shunt should also be filled in correctly. Shunt